John Stokes Chrome

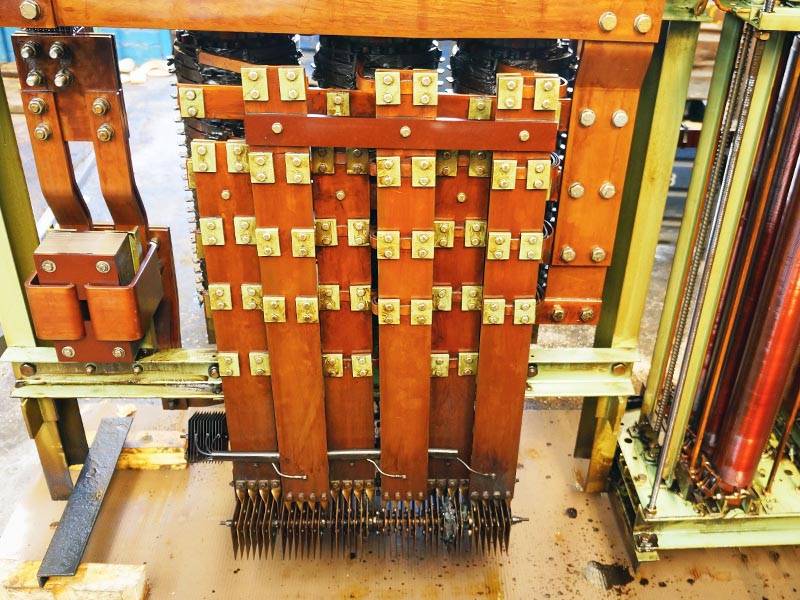

The UK's foremost hard plating specialist

We have prospered through good times and hard times, by always producing Hard Chrome products to the highest of standards whilst achieving rapid turnarounds and offering competitive prices to its customers. Because of this and our constant modernisation and ever improving facilities we now serve a growing portfolio of clients from all around the world.

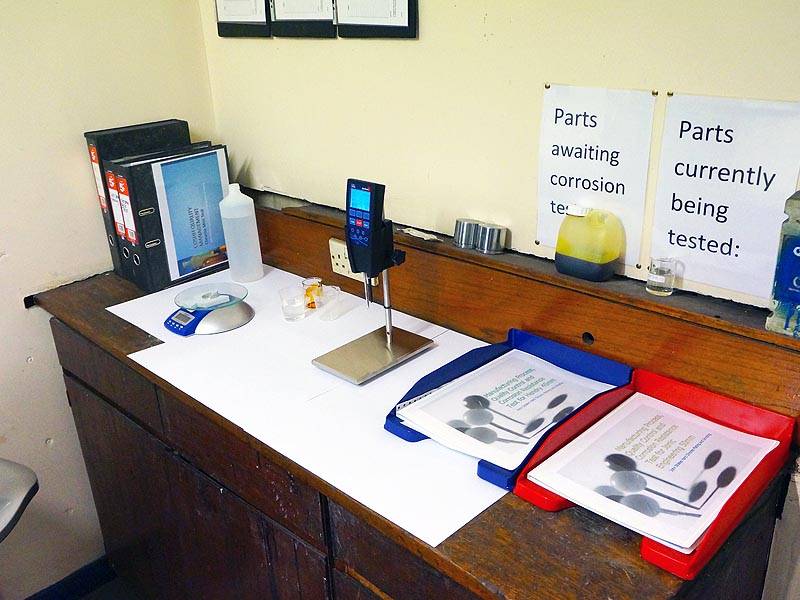

Health & safety improvements

through cutting edge technology

We have now converted all our plating tanks to utilise Anker Dyne 30 surfactant, a foam free and PFOs free mist suppressant chemical which actively changes the density of chrome plating solutions. The effect of this is to reduce the size and diameter of the bubbles created during the electroplating process. Additionally beneficial is the reduction of the energy levels of the bubbles such that negligible emissions occur at the surface of the plating tank. Bubbles simply disperse.

At John Stokes Ltd we are committed to creating the safest production environment we can through the adoption of the latest low impact and low exposure technologies available to us.

Anker Dyne Spec Sheet

R.E.A.C.H

(Registration, Evaluation, Authorisation & restriction of Chemicals)

John Stokes Ltd has forged strong business relationships with McDermid and Enthone Industrial Solutions, two of the worlds largest chemical suppliers. Their expert guidance, along with our investment, is ensuring we are compliant with industry regulations and meet the latest proposed stringent regulations outlined by the EU which come into force within the next 12 months.

Find us.

60 High Street,

Princes End,

Tipton,

West Midlands.

United Kingdom.

DY4 9HP.

Call us.

+44 (0)121 520 6301

Email us.

enquiries@stokeschrome.co.uk